4 Months (Sept. 2023 – Dec. 2023)

Ionic Mechatronics

Mechatronics Engineering Intern

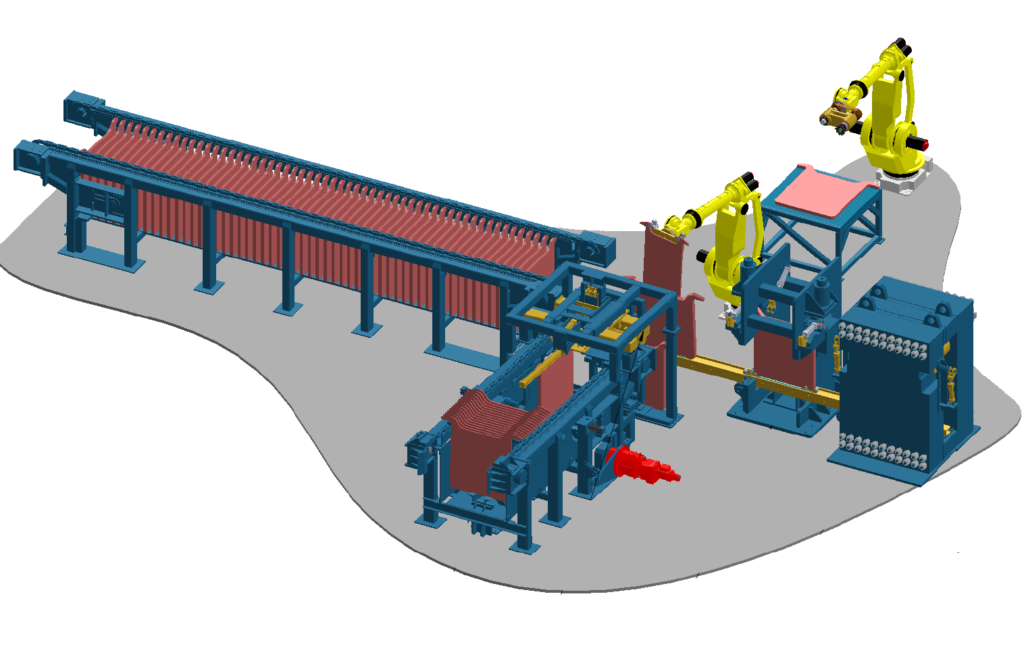

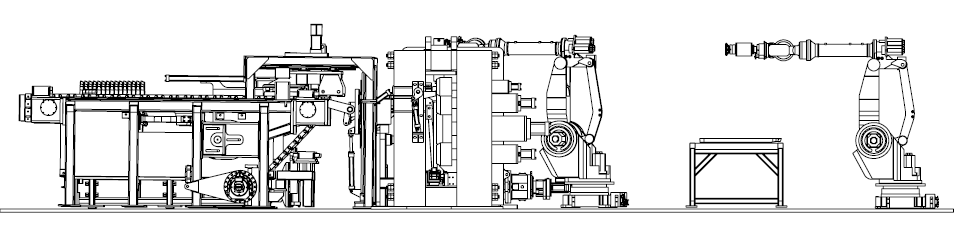

During my internship at a local engineering mining firm in Sudbury, Ontario, I worked as a Mechatronics Intern specializing in designing and developing highly specialized, one-time-use robotic equipment for underground mining applications. Over two months, I contributed to a mining safety device designed for a uranium mine in Alberta. If stuck, it would cut off a mining rod, demonstrating the firm’s focus on creating novel, purpose-driven technologies.

I gained hands-on experience with every step of the engineering design process, particularly during the CAD phase. Each drawing I created was meticulously reviewed, redlined with changes, and then scanned and resubmitted for evaluation, emphasizing the iterative nature of engineering design. This process taught me the critical importance of thorough documentation and precise communication, skills essential for creating reliable and innovative solutions in the engineering field.